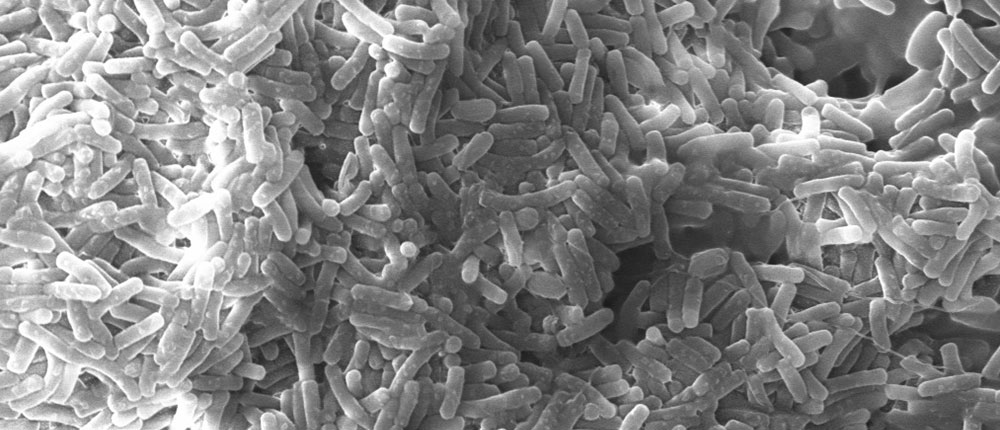

TERI's Oilzapper technology uses naturally occurring microorganisms to transform hydrocarbon contaminants in soil to non-toxic compounds

In Balkum area of Thane in Maharashtra stands Piramal Vaikunth, a residential complex by Piramal Realty, the real estate vertical of the Piramal group. While the project is a few years old, the soil on which it stands has a longer history and is a silent testimony to the science of bioremediation.

Bioremediation is a process that uses naturally occurring microorganisms to transform harmful substances to non-toxic compounds.

"The area where Vaikunth project stands today earlier housed a vitamin manufacturing factory of Piramal Enterprises Limited (PEL). In 2012, the production was shifted elsewhere and the Piramal group wanted to build its first realty project in Thane at the spot," said Suhas Wani, senior manager, corporate EHS, Piramal group.

Oilzapper for soil remediation – TERI's expertise

The waste released from years of pharmaceutical activity had to be cleaned up. Even after the sludge was removed from the spot, the soil was found contaminated with pharmaceutical pollutants including total petroleum hydrocarbons (TPHs), polyaromatic hydrocarbons, heterocyclic organic compounds, phenols, chroforms and other associated compounds. Most of these pollutants are carcinogenic and can cause irritation to skin and soreness in eyes upon exposure. The level of the contaminants was to be reduced to make the soil suitable for disposal without causing environmental pollution. This was also a requirement for the project to get environmental clearance.

In order to restore the site, PEL contracted TERI to conduct bioremediation of the land with its indigenous Oilzapper technology. Oilzapper is used to bioremediate sites polluted by industrial waste. It is a microbial consortium, or a group of chosen microbes, developed by assembling four naturally occurring bacterial species that can degrade different fractions of complex mixture of toxic compounds such as alkanes, alkenes, benzenes, phenolis, heterocyclic organic compounds and TPHs, among others.

Getting to work

At the site of the plant, a total of 11,000 m3 of soil was found to be contaminated with various mixtures of pollutants exceeding the Central Pollution Control Board's (CPCB's) limits. The bioremediation was carried out in two batches, each taking roughly 80 days.

The initial concentration of contaminants in the soil was found to be higher than the standard limit with average TPH level of 3.32% along with other organic chemical compounds. After the end of bioremediation process, the concentration of TPHs was reduced to less than 0.5% and other organic compounds were also brought to standard limits.

"To begin the bioremediation process, soil samples were collected from the site and brought to TERI's Fermentation Technology Research Centre (FTRC) labs in Gurugram, Haryana. Here, apart from determining the contamination levels, beneficial microbes present in the soil were isolated and blended with the existing bacterial culture in Oilzapper to test its suitability for this particular combination of pollutants. A customised microbial combination of Oilzapper was prepared. Once its efficacy was tested, the first batch was prepared and transported to the site," said Veeranna A Channashettar, Fellow, TERI, who was leading the project.

"The contaminated soil was excavated and spread over an HDPE liner. This liner is a High Density Polyethylene geomembrane that was used to prevent percolation of contaminants into the ground. The brown, husk-like Oilzapper was applied on the soil, followed by a specially-designed nutrient mixed with water and sprayed over it to facilitate microbial growth. The soil was mixed thoroughly with JCBs and tilled every week, apart from maintaining its moisture content. Samples were collected and analysed every 15-20 days to check the percentage of degradation of TPHs," he added.

By the end of the bioremediation period, 87% to 93% biodegradation was achieved across various sites in the plant. The final samples (after bioremediation) from each site were analysed for TPH and other toxic parameters to test for their safety.

"TERI is a leader in the field of bioremediation. Our patented Oilzapper technology has elicited tremendous response in India and abroad for the results it has repeatedly shown with hydrocarbon-contaminated soil. It does not require transferring of large quantities of contaminated soil from the site and completely decomposes the contaminants, leaving no toxic byproducts. Both of these qualities were well-suited for the Piramal project. Our association with the company was very fruitful as we received complete support from them in our efforts," said Dr Banwari Lal, Director, Environmental and Industrial Biotechnology division, TERI.

The Piramal group won the National Level Environment, Health and Safety Awards 2015 from the World CSR Day Group for outstanding contribution in the Environment & Safety area for the Piramal project. It was also the bronze winner of the OSH (Occupational Safety and Health) India award for Innovation, again for the same project.

"The project and the subsequent award showed Piramal's approach towards the environment. Such an activity was carried out in the Indian pharmaceutical industry for the first time. Now, if ever a need arises for a bioremediation exercise for any of Piramal's other verticals too, we know we have the experience," said Wani.