Operation Flood catapulted India as the highest producer of milk in the world and the same needs to be replicated to revolutionize the bioenergy sector.

The Central government schemes, such as Sustainable Alternative Towards Affordable Transportation (SATAT) and Galvanizing Organic Bio-Agro Resources Dhan (GOBARdhan), aim to convert organic waste into renewable fuel, support rural livelihoods, and reduce dependence on fossil fuels. To ensure market linkage, the Ministry of Petroleum & Natural Gas has introduced a phased Compulsory Blending Obligation (CBO), requiring Compressed Biogas (CBG) to be blended into City Gas Distribution networks starting at 1% in FY 2025-26 and increasing to 5% from FY 2028-29 onwards. Financial support is being provided through the Ministry of New and Renewable Energy (MNRE’s) National Bioenergy Programme, offering Central Financial Assistance (CFA) to new CBG plants eligible for rupees 4 crore and existing plants for 3 crore per 4,800 kg/day capacity, with a maximum of 10 crore per project. The Oil Marketing Companies (OMCs) are now procuring CBG at 85% of the average retail CNG price, revised up from 80% earlier, and funding is available for pipeline development to inject CBG into gas grids.

India possesses a vast and diverse biomass base that can support a Distributed CBG Production Model. According to the Centre for Science and Environment, India’s feedstock availability comprises 190 million tonnes (mt) of animal and poultry waste, 150 mt of agricultural residue, 62 mt of municipal solid waste (MSW), 50 mt of biomass from sewage treatment plants, and 20 mt of press mud. This biomass potential can support an estimated CBG production capacity of 62 million tonnes per annum, with animal and poultry waste alone accounting for 41 per cent and surplus agri-residues for 32 per cent. While around 108 CBG plants have been commissioned so far, the growth trajectory remains slow, raising concerns and signaling the need for a shift in approach.

One of the key challenges faced by operational projects is the availability, pricing, and consistent supply of feedstock. A major reason behind this issue is the limited participation of farmers in the CBG value chain. Currently, farmers often play a peripheral role, which discourages their active involvement. To address these challenges, a Distributed Production Model—combining decentralized Raw Biogas Plant and centralized CBG Plant is proposed. This would enable better integration of farmers into the CBG ecosystem. Actively involving farmers as partners rather than suppliers can help ease the pressure on biomass availability, stabilize feedstock pricing, and ensure reliable supply chains.

Distributed Production Model

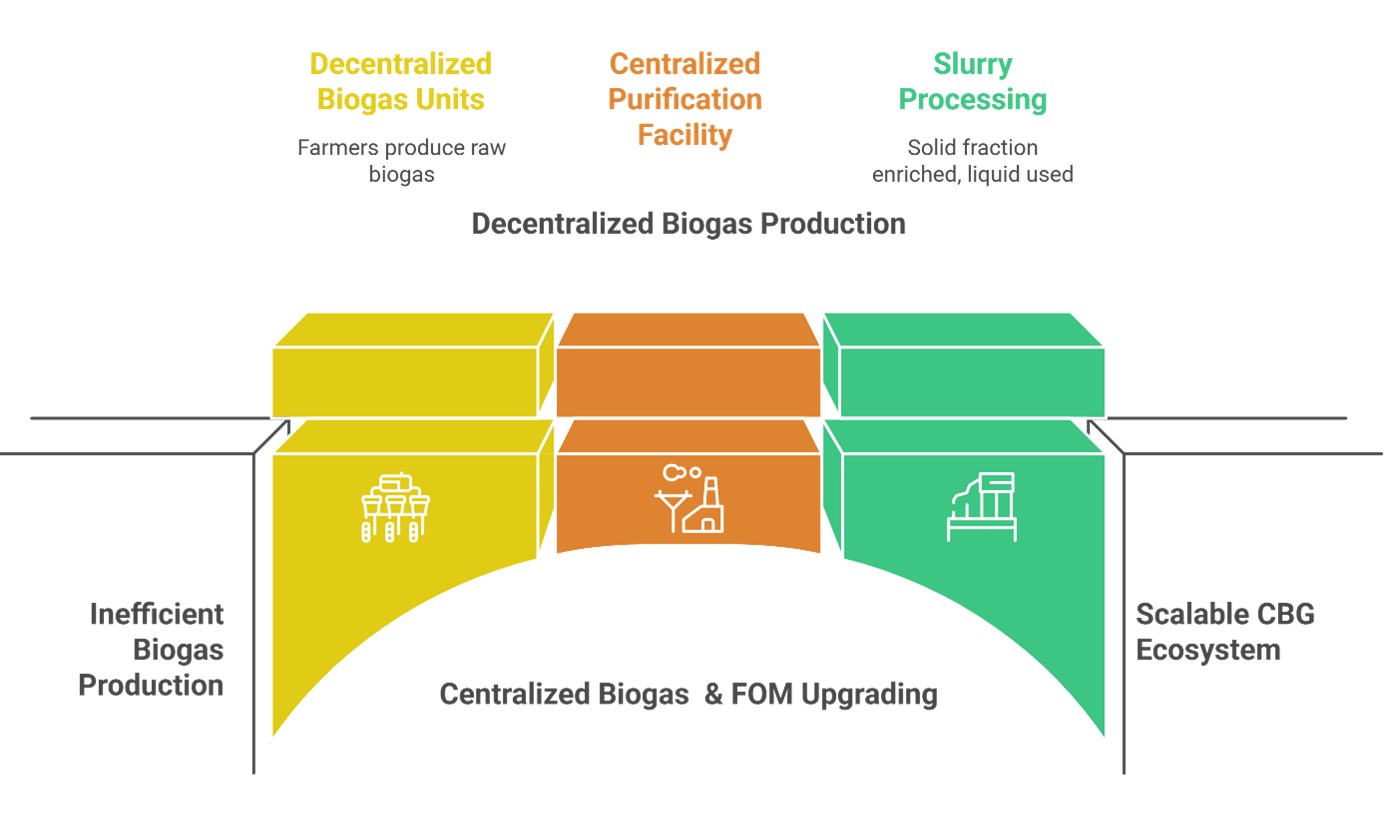

The framework integrates decentralized biogas production units (Figure 1) with centralized biogas and Fermented Organic Manure (FOM) upgrading systems (spoke and hub arrangement), to create a balanced, scalable, and farmer-centric CBG ecosystem.

Figure 1: Framework of decentralized and centralized biogas production model

Medium-scale plants (e.g., 1000 – 5000 m³/day capacity) can be established and operated at the farmer/community level, utilizing locally available biomass and cow dung. This can be in partnership with a private developer. The farmers will source the biomass from their fields and livestock, thus eliminating the need for middlemen in the biomass supply chain.

The raw biogas produced from these units will be transported through a pipeline to a centralized purification facility located near the industry premises, where biogas will be upgraded to industry-grade CBG. Farmers will receive payment based on the volume and methane concentration of the raw biogas supplied to the centralized unit. The key feature of this arrangement will be transparency in measuring the concentration of methane and volume of biogas supplied by the decentralized plants. This is akin to the model established in the milk cooperatives that revolutionized India’s dairy sector. This approach minimizes logistical challenges as well and ensures farmer participation as key stakeholders with an ownership stake. Farmers may hold equity stakes for setting up and operating decentralized biogas plants and receive additional dividends from the overall profits of the CBG plant.

The slurry generated from the biogas plants can be processed through a solid-liquid separator. The solid fraction can be transported to the centralized facility for further enrichment and value addition, while the liquid portion can be utilized locally by nearby farmers on their agricultural fields, mixed with fresh water.

Centralized CBG Plant

- Biogas Upgrading Unit: A centralized facility will be responsible for purifying raw biogas to meet industry-grade standards, ensuring it is suitable for commercial offtake. This unit may be established and operated by the private sector or the industry that requires CBG.

- Digestate Processing Unit/Digestate Upgrading Unit: A dedicated facility will be established to process and upgrade the solid digestate, enhancing its nutrient value and applicability for agricultural use operated and managed by the private developer.

- Pipeline Infrastructure: Streamlined pipeline (Medium-Density Polyethylene [MDPE] pipeline) network, spanning 5–10 km, will connect decentralized biogas production units to the centralized upgrading and processing facilities to be created by the centralized plant owner.

This model has the potential to revitalize and revolutionize the CBG production in India with effective forward and backward linkages.