Spelling 'waste' as 'wealth'

Food is the last thing that comes to mind when one sees rotting and stench-emanating landfills, overflowing with garbage from all over the city. Not surprising then that many will be shocked if they were told that it is an important source in the making of cooking gas.

Of late, there have been experiments to convert the emissions from landfills or garbage dumps to energy so as to power various applications. Though technologies exist, they are crippled with inefficient output and operational problems. The TEAM (T ERI's enhanced acidification and methanation) technology not only overcomes existing shortcomings but also promises to be an important parallel source of fuel for thermal applications, especially cooking.

Distilling the fuel of the future

Tackling mounting waste (produced as a result of growing urbanization and industrialization) has been one of the biggest civic concerns in modern times (Figure 1). Working towards finding a sustainable solution, researchers at TERI zeroed in on biomethanation as the most desirable alternative for the treatment of solid waste, as it yields biogas that can replace conventional fuels and provides digested sludge that can be used as organic manure.

TERI's research culminated in the development of a high-rate digester for fibrous and semi-solid organic waste. The technology has been put to use in the waste treatment plant in TERI's sustainable habitat campus in Gurgaon, Haryana (Figure 2). The plant has been generating good-quality biogas and manure from organic wastes since the year 2000.

The Innovation

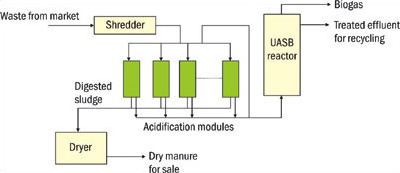

The TEAM process goes through a clean and structured scheme of things (Figure 3). Organic solid waste is cut into small pieces and fed into the acidification reactor. The waste bed is kept submerged in water. Organic acids formed as a result of bed degradation lead to the formation of leachate. This leachate is periodically recirculated through the bed at a predetermined fixed rate to have uniform concentration of microorganisms and nutrients through the bed and to wash off organic acids formed as a result of further bed degradation.

Once a high COD (chemical oxygen demand) concentration is reached, the leachate is extracted in the leachate collection tank. The acidification phase has a retention time of six days; therefore, six such reactors are provided to ensure continuous operation. Anaerobic conditions prevail inside the reactor during the whole process. The phase separation provides suitable environment to the microorganisms in acidification and methanation stages, thus enhancing the activity. (Figure 4). The residue inside the acidification reactor is dried in the sun and then used as manure (Figure 4).

The final concentrated leachate, after pH correction, is fed into the UASB (upflow anaerobic sludge blanket) reactor for methanation. This phase has a retention time of 16 hours. The microbial consortia present in the UASB sludge destroys 90% of the COD, and forms biogas that comprises 70%–75% methane (a high calorific value fuel), carbon dioxide, nitrogen, traces of hydrogen sulphide, and moisture. The biogas production rate is 0.45 m3/kg COD reduced.

The final concentrated leachate, after pH correction, is fed into the UASB (upflow anaerobic sludge blanket) reactor for methanation. This phase has a retention time of 16 hours. The microbial consortia present in the UASB sludge destroys 90% of the COD, and forms biogas that comprises 70%–75% methane (a high calorific value fuel), carbon dioxide, nitrogen, traces of hydrogen sulphide, and moisture. The biogas production rate is 0.45 m3/kg COD reduced.